Serial No.:

Price (ex work):

POA

Description:

Horizontal Spindle

Maximum traverse of headstock in direction of spindle=5 7/8″.

Spindle bore-No. 4 Morse taper.

Spindle adaptable for spring collets up to 11/16″ dia. bore.

Cutter arbor provided with support for staggered tooth cutters up to 5″ dia.

Standard 1″ dia. arbor complete with spacing collars.

Drive

Self-contained drive by standard 1 1/2 h.p., 1425 r.p.m. motor or by two-speed pole changing motor 710/1425 r.p.m. Power transmitted by two “B”‘ section vee belts 56” long.

Spindle Speeds :—

12 with pole changing motor-60, 95, 120, 150, 190, 235, 300, 375, 475, 600, 750 and 1200 r.p.m.

All gears are hardened and ground to ensure smooth running.

Vertical Table

Clamping area 7 3/4″ x 21 5/8″, with 9 7/8″ horizontal traverse and 11 5/8″ vertical traverse.

Feed Screws

All accurately screw cut and equipped with large indicator dials graduated in .001″ divisions.

Automatic table feed engaged by single lever selector

Both horizontal and vertical traverses provided with stop dogs and safety stops arranged for automatic throw out.

Horizontal Traverse Feeds :—

12 with two-speed pole changing motor— 5/16″, 15/32, 5/8”, 11/16”, 15/16”, 1 1/32”, 1 3/8”, 1 9/16”, 2 3/32”, 2 3/8”, 3 1/8” and 4 ¾” per min.

Vertical Traverse Feeds :-

12 with two-speed pole changing motor—3/8”, 19/32”, ¾”, 7/8”, 1 3/16”, 1 5/16”, 1 ¾”, 2”, 2 5/8”, 3”, 4” and 6 1/32” per min.

Dimensions and weights

| Height of machine 55″ with vertical milling head 60½”max. |

|

| Space required 40”x40” | |

| Net weight of the machine | app. 1060 Ibs. |

| Inc. Accessories | Max. app. 1900 Ibs. |

| Weight of packing | app. 300 lbs. |

| Dimensions of packing case | 60″ x 40″ x 34″ |

|

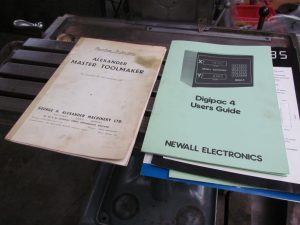

Equipped with Diving head & plate, rotary table, Horizonal equipment, cutters, Tooling guarding, manuals 3axis pro |